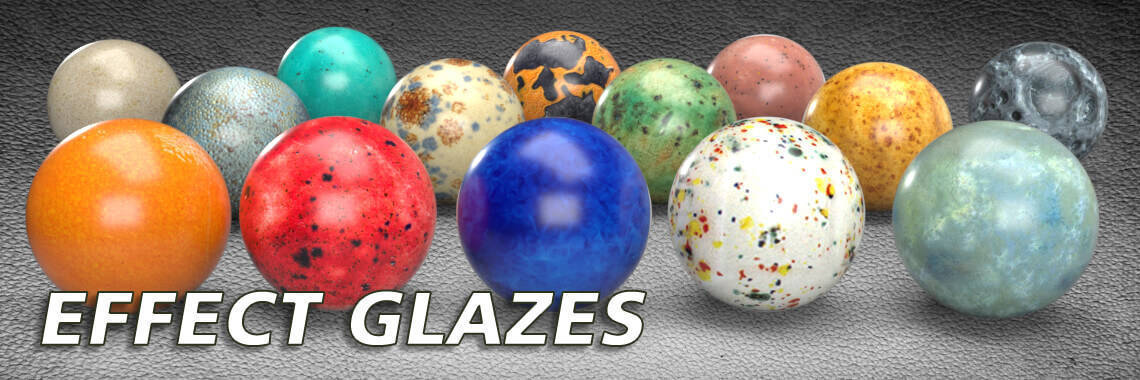

Buy Emerald |BASF | Effect Glazes

Quantity: 40 g. (1.41 oz.) If you need larger quantity, please ask

Firing temperature: 980-1080°C (1800-1976° F) (Orton cone SSB 03½)

Surface: Gloss

Luminescence: Semitransparent

Lead content: lead-free, 0%

Many people want to know what is glaze. Glazing is a technique that requires:

Liquid Glaze is perfect for brush on. It should be coated 2-3 times with a soft brush after first fire. After drying please fire between 1000-1080°C. Shake and stir very well prior to use. If the glaze becomes thickened over time simply add water and stir thoroughly.

Dry glaze is to be dissolved in water to thick paste which should be thinned to proper density. I recommend the proportion - 60%:40% (40g. glaze and 25ml. water). Mellowing and screening before use is pertinent. The glaze density depends on the way of application and on the body porosity. A thick porous bisque, which absorbs the water fast, requires rather a thinner glaze than a tighter, less porous body, which absorbs the water slowly. Each glaze is recommended to be tested with various layers on the body concerned and under determined conditions. The mixing of the glazes is possible in order to change color shade, melting properties or to achieve some artistic effects. Sometimes the glaze coat can crawl due to the presence of dust, grease or dirt on the bisque. Glazed pieces have to be well dried before the firing. The firing temperature should correspond to given data. When fired less, the glaze will be rough and matte, fired hotter, the glaze runs down the piece or soaks into the body.

What is glaze, what is antiquing and other Q/A for painting and glazing can be find in the section: Paint and Glaze.

Effect Glazes Emerald

- Brand: BASF

- Product Code: effect glaze - Emerald - GP082S

- SKU: GP082S

- Availability: Out Of Stock

-

1.35€

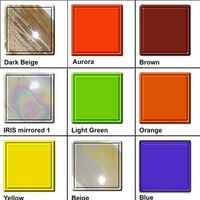

Available Options

Out of Stock

Related Products

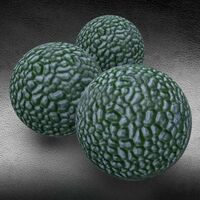

TURTLE SHELL - Effect Glaze Satin Opaque BASF

Quantity: 40 g. (1.41 oz.) Firing temperature: 980-1080°C (1800-1976° F) (Cone 04) Surface..

1.99€

MERCURY - Transform Your Pottery: Discover Mercury Effect Ceramics Glaze

"Mercury Effect Glaze" is a specialized type of glaze used in pottery and ceramics, typically for earthenware. This glaz..

1.49€

SWAMP GREEN - Effect Glaze Satin Cover BASF

Quantity: 40 g. (1.41 oz.) If you need larger quantity, please askFiring temperature: 980-1080°C&nbs..

1.99€

JUPITER - Effect Glaze Satin Semitransparent Degussa

Quantity: 40 g. (1.41 oz.) If you need larger quantity, please askFiring temperature: 980-1080°C&nbs..

1.45€

Tags: basf, glazes, effect, emerald, Emerald, Effect Glazes