Eisenoxid

Fe3O4

Iron(II,III) oxide is the chemical compound with formula Fe3O4. It occurs in nature as the mineral magnetite. It is one of a number of iron oxides, the others being iron(II) oxide (FeO), which is rare, and iron(III) oxide (Fe2O3) which also occurs naturally as the mineral hematite. It contains both Fe2+ and Fe3+ ions and is sometimes formulated as FeO ∙ Fe2O3. This iron oxide is encountered in the laboratory as a black powder. It exhibits permanent magnetism and is ferrimagnetic, but is sometimes incorrectly described as ferromagnetic. Its most extensive use is as a black pigment. For this purpose, it is synthesized rather than being extracted from the naturally occurring mineral as the particle size and shape can be varied by the method of production.

Application

Fe3O4 is used as a black pigment and is known as C.I pigment black 11 (C.I. No.77499) or Mars Black. Fe3O4 is used as a catalyst in the Haber process and in the water-gas shift reaction. The latter uses an HTS (high-temperature shift catalyst) of iron oxide stabilized by chromium oxide. This iron–chrome catalyst is reduced at reactor start up to generate Fe3O4 from α-Fe2O3 and Cr2O3 to CrO3. Bluing is a passivation process that produces a layer of Fe3O4 on the surface of the steel to protect it from rust. Ferumoxytol along with sulfur and aluminium, it is an ingredient in a specific type of thermite useful for cutting steel.

Medical uses

Nano particles of Fe3O4 are used as contrast agents in MRI scanning. Ferumoxytol, sold under the brand names Feraheme and Rienso, is an intravenous Fe3O4 preparation for treatment of anemia resulting from chronic kidney disease. Ferumoxytol is manufactured and globally distributed by AMAG Pharmaceuticals.

Uses in Pottery

There are no limitations to the pottery glazing recipes. Also, there is a multitude of recipes that are the blend of various oxides, minerals, and other substances that create multiple color pallets for glazing. An oxide that is easy to flux offers a perfect color and firm adherence to the pottery, which allows the glaze to become well finished. If you are thinking of working with the iron oxide glaze for your next pottery project venture, then this article is especially for you. Here we are going to talk about everything that you need to know about the iron oxide glaze for your pottery. So, let’s have a look.

What is iron oxide glaze?

Synthetic iron oxide or ferric oxide is used as one of the most common kinds of colorants in ceramics. It contains a higher amount of iron as one of the main components. The iron oxide is quite readily available as a soft and fine powder that is grounded from the ore material. Moreover, the process also includes heat processing of the ferrous or ferric sulfate or ferric hydroxide to create the oxide. The ions present in the mixture produce a similar type of color in the glaze and on the clay surface during firing. The iron oxide glazes are famous for being available in various shades and hues. It is available in both bright and light red to dark maroon shades. The iron oxide glazes are typically designated on a scale of 120–180 to denote the color and shade through its numbering. The oxides in the ceramics need to be fired at a similar temperature, even if the grades are different. As they contain the same amount of iron, they need to be fired at the same temperature. The colors differ due to the degree of grinding.

How does iron oxide react while firing?

In oxidation, the fired ironwork is a very refractory component. Such personality of iron oxide makes it quite impossible to create a metallic glaze even at the highly melted condition. Iron Oxide is a very efficient source for the color palettes like the red-brown maroon, tan, and brown colors in the glaze bodies. The color of the iron depends on the crystallization of iron in the matrix of a fluid glaze. Besides that, it requires a large amount of iron to be present in the glazing mixture to acquire the proper red shade. The terracotta red color comes from the iron, which makes the body a light scarlet shade. Moreover, the color also depends on the porousness of the body. The more you fire the body at a higher temperature, the more acquires the depth in the shade. The color changes from the deeper red to dark brown color due to firing. The reduction in firing changes the personality of the iron, and it becomes very active as a flux. The iron glaze acts with stability at cone 6–8–10 in the oxidation process and usually runs off the ware due to the reduction method. The iron, due to the reduction process, can create lovely shades of the earthy brown color. Moreover, you can also achieve green, red, and grey, depending on the glaze chemistry and the amount of iron present in the mixture. With a particular amount of impurities present in the iron, during the reduction of clay bodies, it can melt faster and acquire fluidic consistency during firing. Thereby, it creates specks that run through the glaze. That is how it makes a beautiful shade of glazing, which is popularly known as blossom on the glazing surface.

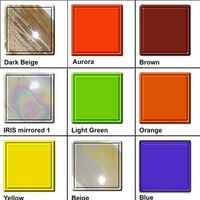

What colors can be created using iron oxide?

You can easily create colors like red, brown, scarlet, black, tan, maroon, grey, green, yellow using a variety of iron oxides. And you need to fire them at a higher temperature. At the reduction phase, the iron oxide creates a brown and tan shade. And the oxidation range emphasizes the reddish hue. You need to fire this glaze at a cone range of 11–12 in the heavy reduction process in a wooden kiln. The mixture also works in a fine, fired gas kiln at a cone range of 10 with normal reduction.

How to decorate your pottery with iron oxide for glazing?

As we said earlier, iron oxide is a popular kind of colorant that you can easily use for decorating your pottery. Designing the porter with iron oxide is much easier if you know how to do it rightly. Here are the ways that you can use to decorate your pottery with iron oxide. You can easily add oxides along with the slips to create a more attractive design. Make some slips for the coloring of your slip. After that, add some oxide to create the color that you want. Now mix the slip properly to get the perfect shade for your glaze. To get an even and uniform color, you need to mix the oxide quite well with the slip until the color blends entirely and creates an even texture of the mixture. On the contrary, if you want a blotchy color or a random shade, there is no need for mixing well.

Characteristics of iron oxide:

Just like any other oxides, iron oxide, or ferric oxide for glazing comes with some of the specific characteristics that you need to know.

Formel: Fe3O4

Molarmass: 231.533 g/mol

Form: solid black powder

CAS Nummer: 1317-61-9

Dichte: 5 g/cm³

Synonyme: Iron oxide(II,III), magnetic nanoparticles solution, Magnetite Nanoparticles, PEG modified Mn-Zn Ferrite (methoxyl group terminal), tri-iron tetroxide, Black Ferric Oxide, Magnetite Dispersion, Magnetite Nanopowder, Mn-Zn Ferrite Nanoparticles, Monodispersed Magnetite Microspheres

Eisenoxid

- Hersteller Degussa

- Artikelnr. Oxide - Iron Tetroxide - Fe3O4

- SKU: Fe3O4

- Verfügbarkeit 808

-

0.59€

Mögliche Optionen

Ähnliche Produkte

Kupfer(I)-chlorid

CuCl Kupfer(I)-chlorid ist eine chemische Verbindung aus Kupfer und Chlor mit der Formel CuCl. Sie ist eine Lewis-S..

0.59€

Graphitpulver: Verbesserung der Leistung und Effizienz von Ruß

C Graphitpulver ist eine Form von Kohlenstoff, der fein zu Pulver vermahlen wird. Es besteht aus geschichteten Kohl..

0.99€

Kaliumbromat (KBrO3)

KBrO3 Kaliumbromat (KBrO3) ist eine chemische Verbindung, die aus Kalium, Brom und Sauerstoff besteht. Es handelt s..

1.99€

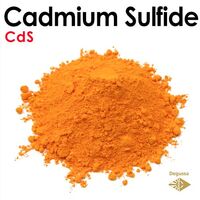

Cadmiumsulfid

CdS Cadmiumsulfid (CdS) ist eine chemische Verbindung, die aus den Elementen Cadmium (Cd) und Schwefel (S) besteht...

1.19€

Schnellsuche oxid