Staining Clay Ceramic Pigments, Stains, pottery color

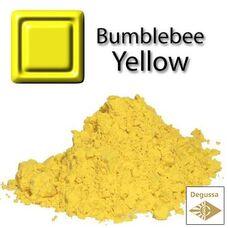

BUMBLEBEE YELLOW - Ceramic Pigments and Stains Degussa Colours

BUMBLEBEE YELLOW color powder mixed with water provides the cheapest and the most usual way of applying underglaze decor..

0.99€

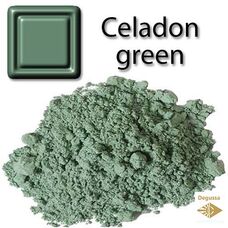

CELADON GREEN - Ceramic Pigments and Stains Degussa Colours

CELADON GREEN color powder mixed with water provides the cheapest and the most usual way of applying underglaze decorati..

0.99€

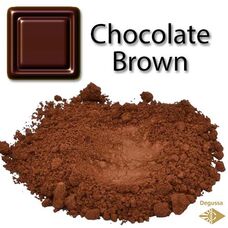

CHOCOLATE BROWN - Ceramic Pigment DEGUSSA

CHOCOLATE BROWN color powder mixed with water provides the cheapest and the most usual way of applying underglaze d..

0.79€ 0.99€

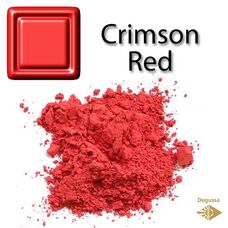

CRIMSON RED - Ceramic Pigments and Stains Degussa Colours

CRIMSON RED color powder mixed with water provides the cheapest and the most usual way of applying underglaze decoration..

1.99€

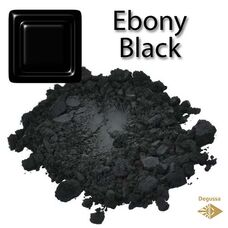

EBONY BLACK - Ceramic Pigments and Stains Degussa

Color code: 232323Firing temperature: 890-1100°C (1640-2014°F) Lead content: lead-free, 0%..

0.99€

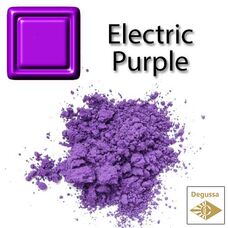

ELECTRIC PURPLE - Ceramic Pigments and Stains Degussa Colours

ELECTRIC PURPLE color powder mixed with water provides the cheapest and the most usual way of applying underglaze decora..

2.99€

FIRE ORANGE - Ceramic Pigments and Stains Degussa Colours

FIRE ORANGE color powder mixed with water provides the cheapest and the most usual way of applying underglaze decoration..

1.99€

FRENCH GREY - Ceramic Pigments and Stains Degussa Colours

FRENCH GREY color powder mixed with water provides the cheapest and the most usual way of applying underglaze decoration..

0.99€

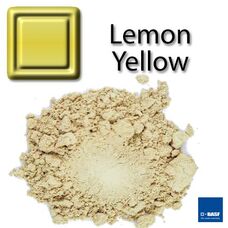

LEMON YELLOW CRAYOLA - Ceramic Pigment Stain China

LEMON YELLOW color powder mixed with water provides the cheapest and the most usual way of applying underglaze decoratio..

0.99€

LILAC PURPLE - Ceramic Pigment Degussa

LILAC PURPLE color powder mixed with water provides the cheapest and the most usual way of applying underglaze decoratio..

1.99€

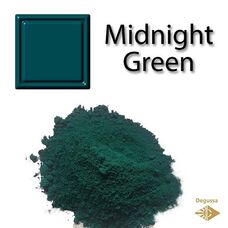

MIDNIGHT GREEN - Ceramic Pigments and Stains Degussa Colours

MIDNIGHT GREEN (sometimes also called Eagle green) is a dark cyan. It has been the primary team color for the Natio..

0.99€

PRUSSIAN BLUE - Ferric ferrocyanide, Iron hexacyanoferrate - A Journey into Berlin Blue: History, Chemistry, and Applications

Fe4[Fe(CN)6]3 Prussian Blue is a deep blue pigment that has been used in various applications, including art,..

1.59€ 1.99€

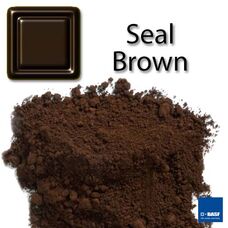

SEAL BROWN - Ceramic Pigment Degussa

SEAL BROWN color powder mixed with water provides the cheapest and the most usual way of applying underglaze decoration...

0.99€

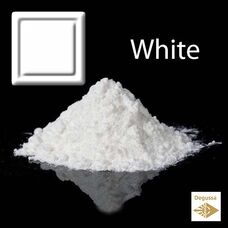

WHITE - Ceramic Pigments and Stains Degussa Colours

WHITE color powder mixed with water provides the cheapest and the most usual way of applying underglaze decoration. Glaz..

0.79€ 0.99€

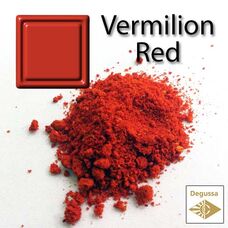

VERMILION RED - Cinnabar Ceramic Pigments Stains High Temperature Porcelain up to 1300 centigrade

VERMILION RED or CINNABAR is the highest quality color. Mixed with water provides the cheapest and the most usual way of..

2.99€

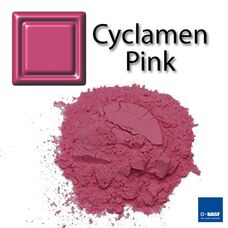

CYCLAMEN PINK - Ceramic Pigments and Stains Degussa

Many people want to know what is glaze. Glazing is a technique that requires:Prepared ceramic pigments, commonly referre..

0.99€

SAPPHIRE - Pigments, Stains, Oxides Degussa made in Germany HQ

Color code: 0F52BA Quantity: 10 g. (0,35 oz.) Firing temperature: 890-1160°C (1640-2120° F) (up..

0.99€

Cobalt Blue - Ceramic Pigments and Stains Degussa Colours

Color code: 0047AB Quantity: 10 - 450g.Firing temperature: 890°C - 1300°C (1640°F - 2380°F) (up..

1.59€

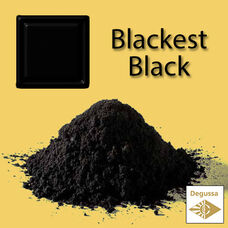

BLACKEST BLACK - Ceramic Pigment Jet Black High Temperature Porcelain up to 1300 centigrade

BLACKEST BLACK color powder mixed with water provides the cheapest and the most usual way of applying underglaze decorat..

1.19€

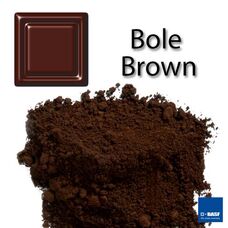

BOLE BROWN - Ceramic Pigment Degussa

BOLE BROWN color powder mixed with water provides the cheapest and the most usual way of applying underglaze decora..

0.79€ 0.99€

BROWN SUGAR - Ceramic Pigment Degussa

BROWN SUGAR color powder mixed with water provides the cheapest and the most usual way of applying underglaze decoration..

0.99€

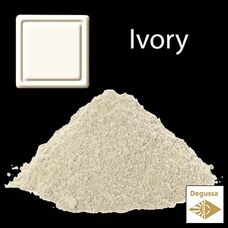

IVORY - Ceramic Pigment Off-White Porcelain

IVORY color powder mixed with water provides the cheapest and the most usual way of applying underglaze decoration. Glaz..

1.11€

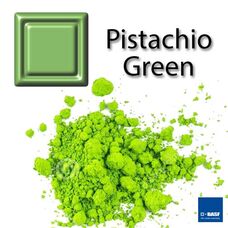

PISTACHIO GREEN - Ceramic Pigments and Stains Pistachio Color

PISTACHIO GREEN color powder mixed with water provides the cheapest and the most usual way of applying underglaze d..

0.99€

ARCTIC BLUE - Ceramic Pigments and Stains Degussa Colours

Many people want to know, what arctic blue color is, how to paint pottery arctic colours:Prepa..

0.99€