Gold luster and fritware production and distribution enamels

BEIGE - Precious metal Luster Lustre for overglaze application

Quantity: 10 g. (0,35 oz.)Firing temperature: 700-830°C (1300-1540°F) (up to Orton cone SSB 014) Lead con..

5.79€

CINNAMON ORANGE - Precious metal Luster Lustre for overglaze application

The ceramic lustres are organic compounds of precious metals and base metals offered in the form of finished paint which..

3.19€

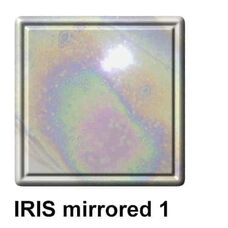

IRIS 1 - Mirror Effect Luster Lustre - Mother of Pearl

Quantity: 10 g. (0,35 oz.)Firing temperature: 700-830°C (1300-1540°F) (up to Orton cone SSB 014) Lead con..

5.59€

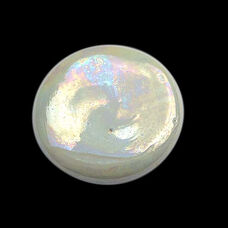

IRIS 2 (Mother of Pearl) Precious metal Luster for overglaze application

The ceramic lustres are organic compounds of precious metals and base metals offered in the form of finished paint which..

5.99€

SMOKY BROWN - Precious metal Ceramics Luster Lustre for overglaze application

Smoky Brown luster for overglaze application in ceramics refers to a specific type of luster finish that imparts a metal..

14.99€

YELLOW - Precious metal Ceramics Luster Lustre for overglaze application

Yellow luster for overglaze application in ceramics is a type of decorative finish that can be applied to the surface of..

19.99€

GREY - Precious metal Luster Lustre Heraeus for overglaze application

The lustres are organic compounds of precious metals and base metals offered in the form of finished paint which is appl..

6.69€

TAWNY ORANGE - Precious metal Luster Lustre for overglaze application

The lustres are organic compounds of precious metals and base metals offered in the form of finished paint which is appl..

3.59€

DARK BEIGE - Precious metal Luster Lustre for overglaze application by Heraeus

The ceramic lustres are organic compounds of precious metals and base metals offered in the form of finished paint which..

14.99€

LIME - Yellow/Green Precious metal Ceramic Luster Lustre for overglaze application

The ceramic lustres are organic compounds of precious metals and base metals offered in the form of finished paint which..

29.00€

ANTIQUE BRONZE - Green Precious metal Luster Lustre for overglaze application Heraeus

The ceramic lustres are organic compounds of precious metals and base metals offered in the form of finished paint which..

12.47€

ORANGE - Precious metal Luster Lustre for ceramics overglaze application

The ceramic lustres are organic compounds of precious metals and base metals offered in the form of finished paint which..

3.19€

Balsamic Turpentine - Thinner (diluent) for Lustre Luster

DescriptionTurpentine (which is also called gum turpentine, the spirit of turpentine, oil of turpentine, wood turpentine..

2.18€

Pine Turpentine - thinner (diluent) for lustre

Quantity: 3 ml. (0,10 fl. oz.) For larger quantity, please contact me. Description: The Turpentine i..

1.99€

DARK TURQUOISE BLUE - Precious metal Luster Lustre for overglaze application Heraeus

The ceramic lustres are organic compounds of precious metals and base metals offered in the form of finished paint which..

59.00€

AURORA - Precious metal Luster Lustre for overglaze application Heraeus

Quantity: 10 g. (0,35 oz.)Firing temperature: 700-830°C (1300-1540°F) (up to Orton cone SSB 014) Lead con..

15.99€

CARMINE - Heraeus Precious Metal Luster Lustre Germany effect

The lustres are organic compounds of precious metals and base metals offered in the form of finished paint which is appl..

29.00€

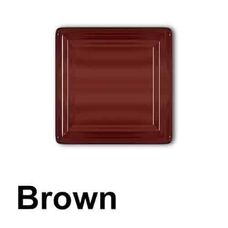

Dark Brown

Quantity: 10 g. (0,35 oz.)Firing temperature: 700-830°C (1300-1540°F) (up to Orton cone SSB 014) Lead con..

6.99€

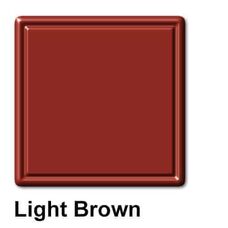

Light Brown

Quantity: 10 g. (0,35 oz.)Firing temperature: 700-830°C (1300-1540°F) (up to Orton cone SSB 014) Lead con..

5.49€

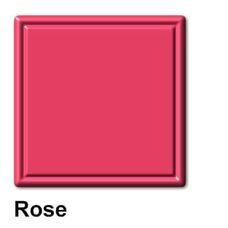

ROSE - Precious metal Gold Lustre for overglaze application

The ceramics lustres are organic compounds of precious metals and base metals offered in the form of finished paint whic..

29.00€